We hung some curtains in the Kitchen and the results can be seen below.

Below is the same shot from 3 years ago:

We hung some curtains in the Kitchen and the results can be seen below.

Below is the same shot from 3 years ago:

Poor man’s stat mechanism (see here if you’re a stat nut)

I like to do this every now and then to see what the percentages are. Obviously Win percentage is a pretty hard number. Overall race wins is probably a better statistic and adding in top 5 and 10 positions would be good.

Championships are the true measure and Stewart-Haas seems to be doing pretty well with 2 in the last couple of years and of course, Penske’s first.

I am now on to building cabinets for the house. Cabinets for the kitchen, built-ins and the like.

I thought I would document what I was doing

Part 1

The first thing to do is to have the necessary tools. It doesn’t have to be anything fancy but you want them to be in good shape, be able to cut straight, etc.

I have a nice table saw with plenty of power (Steel City), a chop saw, sander(s), a Kreg jig and screws.

I also built a box that helps me do cross cuts on the table saw for material that is to large for the chop saw such as 24” wide plywood.

You could certainly use a Skil saw if that’s all you have plus some nice straight lengths of wood and some clamps. Use the straight lengths of wood as guides for your cuts. Clamp them down to keep them in place.

Here is my jig (and table saw with the out table and dust collector):

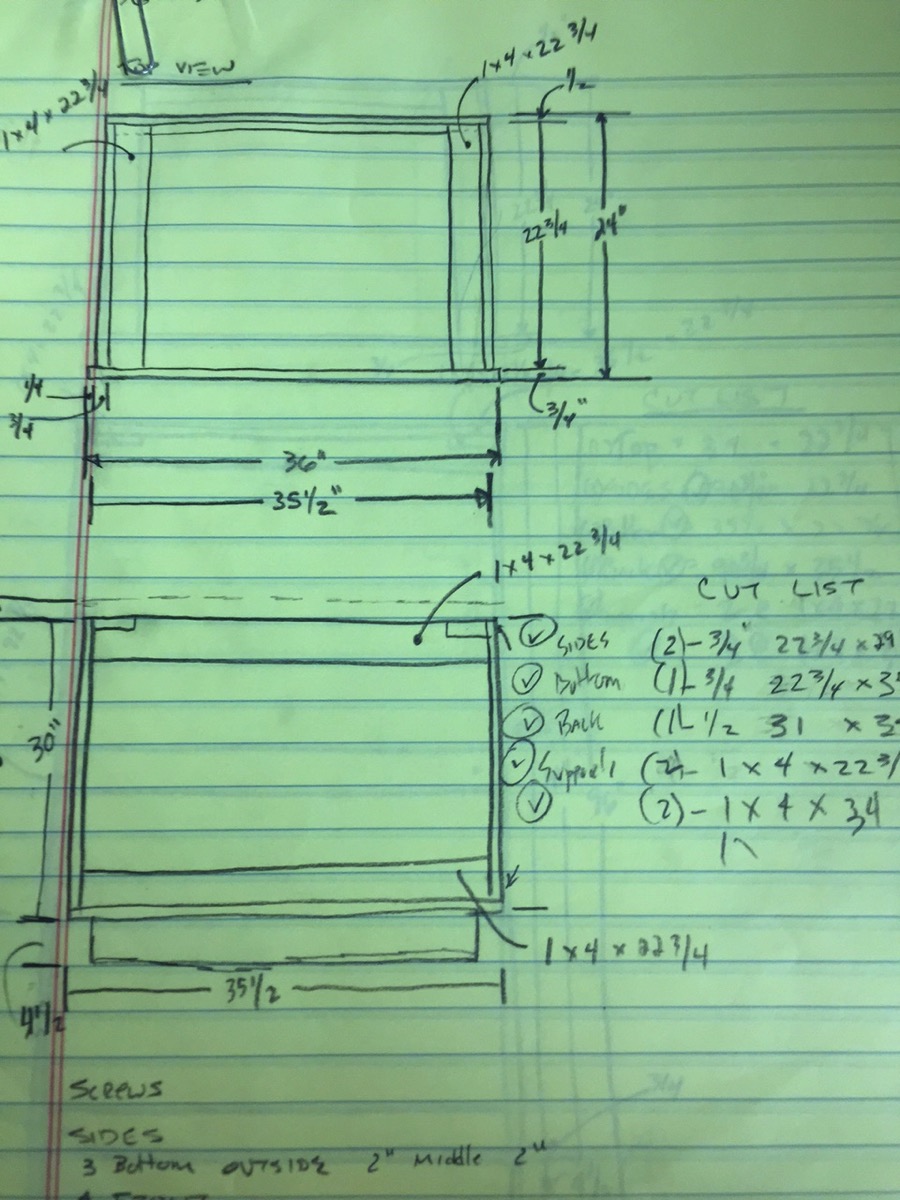

Once you have the tools and naturally a place to do the work you need a plan for building the cabinets. Below is a shot of the plan that I have for my 36” base cabinets. This allows me to review with cut list and know with certainty what I need and just simply do the cutting.

With your plan in in your hand, review the cut list and start cutting the pieces to match cut list. When making your cuts make sure to keep the kerf (the width of the blade). I forgot about it…once. Hence why you see the plans above.

You will end up with a pile of wood that looks something like what you see below. The 1×4’s are used for the base. The pile of plywood contains three pieces for each cabinet.

This pile needs to 1×4 supports to be cut as well as the bit of 1/2” plywood that will make up the back of the cabinet.

Below is an image of our deck after a bit of cleaning and gently power washing.

We used Restore on the deck after replacing about 1/3rd of the 2×4’s on the deck. We sanded the entire thing with power sander (again gently) and applied the Restore. That was 2 years ago. One thing that we did was use a small roller that was the width of the 2×4’s and SLOWLY applied the material. We then used a small putty knife between the joints to clear the material. Doing so kept the material from crossing the joints.

One side effect of this is that we used considerably less material than we anticipated given the size of this deck and a smaller secondary deck we repainted as well.

Very happy with the results.

This is the deck midway through the reconstruction back in August of 2013. Note the pepto-bismal pink color. Lovely, no?

A little more work on the pantry. Cut the shelves, put up the supports, installed the shelves.

New project after the table. When we bought the house we pulled out all of the shelves in the closets because they were horrible. This particular closet is off the kitchen and is going to be used as a pantry. The configuration of the walls in the closet is a bit goofy as the walls form an arrow that points the right in the picture.

Long story short is that I will cut some shelves out of 3/4 plywood to match the shape, nail supports to the wall all the around for the shelves and paint the whole thing white.

Here is the table with a bit of Molly work on it.

Here is the table after the last little bit of work.

Pretty basic table. 2×4’s and 2×6’s. I still have to attach two shelves underneath. This picture also shows the need to finish the trim work!

Nice update from The Wirecutter. Good to see Apple taking a release cycle to polish things up.

See here.